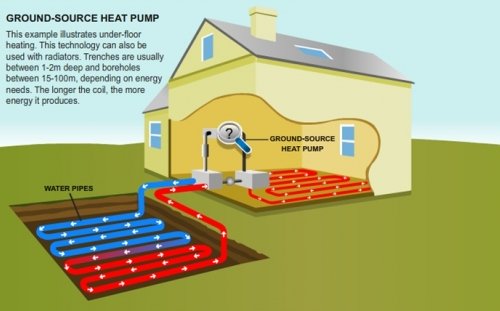

Ground source heat pumps (GSHPs) use pipes that are buried in the garden to extract heat from the ground. This heat can then be used to heat radiators, underfloor or warm air heating systems and hot water in your home.

A ground source heat pump circulates a mixture of water and antifreeze around a loop of pipe, called a ground loop, which is buried in your garden.

Heat from the ground is absorbed into the fluid and then passes through a heat exchanger into the heat pump.

The ground stays at a fairly constant temperature under the surface, so the heat pump can be used throughout the year.

The length of the ground loop depends on the size of your home and the amount of heat you need.

Longer loops can draw more heat from the ground, but need more space to be buried in. If space is limited, a vertical borehole can be drilled instead.

The benefits of ground source heat pumps

- Could lower your fuel bills, especially if you replace conventional electric heating

- Could provide you with income through the government’s Renewable Heat Incentive (RHI)

- Could lower home carbon emissions, depending on which fuel you are replacing

- No fuel deliveries needed

- Can heat your home as well as your water Minimal maintenance required

Unlike gas and oil boilers, heat pumps deliver heat at lower temperatures over much longer periods.

During the winter they may need to be on constantly to heat your home efficiently. You will also notice that radiators won't feel as hot to the touch as they might do when you are using a gas or oil boiler.

Air source heat pumps are usually easier to install than ground source as they don't need any trenches or drilling, but they are often less efficient than ground source heat pumps.

How do ground source heat pumps work?

Heat from the ground is absorbed at low temperatures into a fluid inside a loop of pipe (a ground loop) buried underground. The fluid then passes through a compressor that raises it to a higher temperature, which can then heat water for the heating and hot water circuits of the house.

The cooled ground-loop fluid passes back into the ground where it absorbs further energy from the ground in a continuous process as long as heating is required.

If there is enough space, the collector loop can be laid horizontally in a trench about a metre or so below ground. Where there isn’t room to do this you can drill vertical boreholes to extract heat from much further down, typically 90 – 160 metres deep.

The space you need for a horizontal loop, and the depth you need for a borehole, will depend on many factors – your heat pump installer will design the collector array based on local conditions and the heat requirements of your home.

Heat pumps have some impact on the environment as they need electricity to run, but the heat they extract from the ground, the air, or water is constantly being renewed naturally.

Is a ground source heat pump suitable for me?

To tell if an air source heat pump is right for you, there are a few key questions to consider:

Things to Consider :

- Is your garden/Business suitable for a ground loop? It doesn't have to be particularly big, but the ground needs to be suitable for digging a trench or a borehole and accessible to digging machinery.

- Is your home/Business well insulated? Since ground source heat pumps work best when producing heat at a lower temperature than traditional boilers, it's essential that your home is well insulated and draught-proofed for the heating system to be effective.

- What fuel will you be replacing? The system will pay for itself much more quickly if it's replacing an electricity or coal heating system. Heat pumps may not be the best option for homes using mains gas.

- What type of heating system will you use? Ground source heat pumps can perform better with underfloor heating systems or warm air heating than with radiator-based systems because of the lower water temperatures required.

- Is the system intended for a new development? Combining the installation with other building work can reduce the cost of installing the system.

Costs, savings and financial support

Costs

Installing a typical system costs around £10,000-£18,000. Running costs will depend on a number of factors including the size of your home and how well insulated it is.

Savings

How much you can save will depend on what system you use now, as well as what you are replacing it with. Your savings will be affected by:

- Your heat distribution system. Underfloor heating can be more efficient than radiators because the water doesn’t need to be so hot. If underfloor heating isn’t possible, use the largest radiators you can. Your installer should be able to advise on this.

- Your fuel costs. You will still have to pay fuel bills with a heat pump because they are powered by electricity, but you will save on the fuel you are replacing. If the fuel you are replacing is expensive you are more likely to make a saving.

- Your old heating system. If your old heating system was inefficient, you are more likely to see lower running costs with a new heat pump.

- Using the controls. Learn how to control the system so you can get the most out of it. You will probably need to set the heating to come on for longer hours, but you might be able to set the thermostat lower and still feel comfortable. Your installer should explain to you how to control the system so you can use it most effectively.

These are the savings you might make every year when replacing an existing heating system in a typical well insulated four-bedroom detached home with an average ground source heat pump installation

England, Scotland and Wales

| Existing System | Fuel bill savings (£/year) | Renewable Heat Incentive (RHI) payment (£/year) January 2018 to 31 March 2018 |

Carbon dioxide savings (kg CO2/year) |

|---|---|---|---|

| Gas old (G-rated) boiler Gas new (A-rated) boiler |

£475 to £535 £175 to £185 |

£2,405 to £2,830 | 2,900 to 3,300 kg CO2 1,500 to 1,700 kg CO2 |

| Electric (old storage heaters) Electric (new storage heaters) |

£1,210 to £1,485 £840 to £985 |

4,300 to 5,200 kg CO2 3,200 to 3,700 kg CO2 |

|

| Oil old (G-rated) boiler Oil new A-rated) boiler |

£695 to £805 £260 to £300 |

6,200 to 7,300 kg CO2 2,200 to 2,500 kg CO2 |

|

| LPG old (G-rated) boiler LPG new (A-rated) boiler |

£995 to £1,145 £455 to £520 |

3,500 to 4,000 kg CO2 1,800 to 2,100 kg CO2 |

|

| Coal | £455 to £535 | 5,500 to 6,400 kg CO2 |

Northern Ireland

| Existing System | Fuel bill savings (£/year) | Carbon dioxide savings (kg CO2/year) |

|---|---|---|

| Typical non-condensing Gas boiler | £200 to £220 | 1.6 Tonnes to 1.8 Tonnes CO2 |

| Old Electric heating system | £1,210 to £1,485 £840 to £985 |

4,300 to 5,200 kg CO2 3,200 to 3,700 kg CO2 |

| Oil old (G-rated) boiler Oil new A-rated) boiler |

£815 to £970 | 3.0 Tonnes to 3.6 Tonnes CO2 |

| Typical non-condensing Oil boiler | £210 to £245 | 2.3 Tonnes to 2.6 Tonnes CO2 |

| Typical non-condensing LPG boile | £800 to £915 | 2.0 Tonnes to 2.3 Tonnes CO2 |

| Coal | £315 to £380 | 5.5 Tonnes to 6.4 Tonnes CO2 |

Figures are based on fuel prices as of April 2019.

NOTE: The Renewable Heat Incentive is no longer available in Northern Ireland.

Financial support

You may be able to receive payments for the heat you generate using a heat pump through the UK Government’s Renewable Heat Incentive.

Domestic RHI is no longer available in Northern Ireland - details of the previous scheme can be viewed at NI Direct.

Maintenance

Heat pump systems typically come with a warranty of two to three years. Workmanship warranties for heat pumps can last up to 10 years, for example through QANW (Quality Assured National Warranties).

Many manufacturers also offer optional extensions of warranty for a fee.

You can expect them to operate for 20 years or more, but they do require regular scheduled maintenance.

A yearly check by you and a more detailed check by a professional installer every three to five years should be sufficient.

The installer should leave written details of any maintenance checks you should undertake to ensure everything is working properly. Consult with your supplier for exact maintenance requirements before you commit to installing a heat pump.

The Ground Source Heat Pump Association says there is no need for safety checks for ground source heat pumps and routine maintenance requirements are very low.

These may include pre-heating season checks of the water pump, external pipes and fittings and electronics.